But what sets our process apart, and how do our customer success stories reflect our expertise?

So, rest assured, if you're in Affordable Polybutylene Pipe Replacement Surrey, you're within our reach, and we're here to ensure your property's plumbing is in the best possible condition.

It suggests the interior of your pipes is degrading, potentially releasing particles into your water supply. By proactively replacing these pipes, you're eliminating a major concern, making your property more attractive on the market. Polybutylene, once hailed for its low cost and easy installation, has shown a propensity to break down over time due to chlorine in municipal water supplies. Understanding the risks associated with polybutylene pipes is crucial, but recognizing the signs of failing plumbing in your home is the next step. Polybutylene pipe failure can wreak havoc on your home's infrastructure, leading to costly and extensive repairs.

Choosing Canyon Property Projects means you're not just addressing a pressing issue; you're investing in your home's future.

You're not alone if you're facing this issue. It's crucial to address this dilemma head-on by considering the replacement of your polybutylene pipes before they fail catastrophically. First off, you'll have to find a reliable plumber or contractor experienced in this type of work. Beyond the immediate improvement in water quality, you'll see a significant uptick in your property's market value. If you're experiencing a gradual or sudden drop in pressure, it could mean your pipes are failing from within, either due to blockages or breaks.

Don't forget to secure pets and inform all household members about the upcoming work. Plumbing and heating Each member of our team has undergone rigorous training programs, certified by industry-leading bodies, emphasizing both practical skills and the latest safety standards. With Canyon Property Projects Ltd, you're in capable hands. You're just steps away from ensuring the safety and longevity of your property's plumbing system.

Even small leaks can quickly escalate, leading to water damage in your home. By addressing the problem now, you're avoiding costly emergency repairs down the line. Their communication was top-notch, keeping us informed every step of the way. Before exploring how to address the issues with polybutylene, it's essential you understand what these pipes are and why they were so widely used.

This proactive approach demonstrates your commitment to maintaining high-quality living conditions, fostering a sense of trust and loyalty among your residents. Let's show you why we're the right choice for your polybutylene pipe replacement needs.

Here's what you need to do:First, clear the work area. This identification is crucial because polybutylene is known for its susceptibility to breakage, leading to costly water damage. Ignoring it won't make it go away and will only lead to bigger issues down the road. These pipes, commonly installed between the late 1970s and mid-1990s, are often gray, blue, or black and have a somewhat plastic, flexible feel.

Being proactive about replacing these pipes can save you a headache and a hefty sum in the long run. Firstly, ensure that the project plan includes clear safety protocols. They'll remove the old polybutylene pipes and install high-quality alternatives that are both durable and meet current standards.

Plus, they'll provide you with maintenance tips and practices to extend the life of your new plumbing system, keeping your home safe and your water flowing smoothly for years to come. Their solution not only addresses the immediate vulnerabilities of polybutylene pipes but also introduces long-term benefits that go beyond simple pipe replacement. You mightn't even know there's a problem until the damage is done.

You mightn't even realize you've got them until a leak springs. Moreover, choosing Canyon Property Projects means you're opting for peace of mind. Water filtration systems These materials are designed to withstand the test of time, ensuring you won't face the same issues again in the foreseeable future.

However, it didn't take long for their dark side to surface. If you're unsure or can't fully inspect your property, consider hiring a professional. We hope this clears up your main concerns. On the other hand, PEX is gaining popularity for its flexibility, ease of installation, and resistance to scale and chlorine damage. Plumbing project estimates

You're left dealing with the aftermath, which often involves costly repairs and a whole lot of hassle. And in case you're worried about after-service support, they've got you covered. Beyond enhancing safety, upgrading from polybutylene pipes can significantly boost your property's market value.

Replacing polybutylene pipes offers significant benefits, including enhanced water quality and increased property value. You're likely wondering why these pipes are such a headache. First, you'll want to reach out to our team. Plumbing contractors

After the assessment, you'll get a detailed plan outlining the replacement strategy. During this initial consultation, you'll discuss your property's needs and the issues you're facing with your current polybutylene pipes. Plus, their service comes with a promise of durability and peace of mind, backed by a comprehensive warranty.

We understand the inconvenience of plumbing problems, so we're committed to getting your life back to normal as quickly as possible. You're likely looking for a team that not only understands the intricacies of polybutylene piping but also appreciates the unique challenges your property might present. Our experts will inspect your property's plumbing and provide a detailed quote and timeline. Replacing polybutylene pipes is crucial for homeowners due to their high risk of failure and potential for costly damage. Evaluating the cost of replacing polybutylene pipes and exploring your financing options is a crucial step before initiating the project.

Polybutylene pipes are known for their likelihood to fail, which can be a red flag for potential buyers. Don't wait for a complete failure.

This article has multiple issues. Please help improve it or discuss these issues on the talk page. (Learn how and when to remove these messages)

|

A contractor[1][2] (North American English) or builder (British English),[3][4] is responsible for the day-to-day oversight of a construction site, management of vendors and trades, and the communication of information to all involved parties throughout the course of a building project.[5]

In the United States, a contractor may be a sole proprietor managing a project and performing labor or carpentry work, have a small staff, or may be a very large company managing billion dollar projects. Some builders build new homes, some are remodelers, some are developers.[6]

A general contractor is a construction manager employed by a client, usually upon the advice of the project's architect or engineer.[7] General Contractors are mainly responsible for the overall coordination of a project and may also act as building designer and construction foreman (a tradesman in charge of a crew).

A general contractor must first assess the project-specific documents (referred to as a bid, proposal, or tender documents). In the case of renovations, a site visit is required to get a better understanding of the project. Depending on the project delivery method, the general contractor will submit a fixed price proposal or bid, cost-plus price or an estimate. The general contractor considers the cost of home office overhead, general conditions, materials, and equipment, as well as the cost of labor, to provide the owner with a price for the project.

Contract documents may include drawings, project manuals (including general, supplementary, or special conditions and specifications), and addendum or modifications issued prior to proposal/bidding and prepared by a design professional, such as an architect.The general contractor may also assume the role of construction manager, responsible for overseeing the project while assuming financial and legal risks.There are several types of risks can occur include cost overruns, delays, and liabilities related to safety or contract breaches.

Prior to formal appointment, the selected general contractor to whom a client proposes to award a contract is often referred to as a "preferred contractor".[8]

A general contractor is responsible for providing all of the material, labor, equipment (such as heavy equipment and tools) and services necessary for the construction of the project. A general contractor often hires specialized subcontractors to perform all or portions of the construction work. When using subcontractors, the general contractor is responsible for overseeing the quality of all work performed by any and all of the workers and subcontractors.

It is a best practice for general contractors to prioritize safety on the job site, and they are generally responsible for ensuring that work takes place following safe practices.

A general contractor's responsibilities may include applying for building permits, advising the person they are hired by, securing the property, providing temporary utilities on site, managing personnel on site, providing site surveying and engineering, disposing or recycling of construction waste, monitoring schedules and cash flows, and maintaining accurate records.[9]

The general contractor may be responsible for some part of the design, referred to as the "contractor's design portion" (JCT terminology).[10]

In the United Kingdom, Australia and some British Commonwealth countries, the term 'general contractor' was gradually superseded by builders during the early twentieth century.[citation needed] This was the term used by major professional, trade, and consumer organizations when issuing contracts for construction work, and thus the term 'general contractor' fell out of use except in large organizations where the main contractor is the top manager and a general contractor shares responsibilities with professional contractors.

General contractors who conduct work for government agencies are often referred to as "builders". This term is also used in contexts where the customer's immediate general contractor is permitted to sub-contract or circumstances are likely to involve sub-contracting to specialist operators e.g. in various public services.

In the United States and Asia, the terms general contractor (or simply "contractor"), prime contractor and main contractor are often interchangeable when referring to small local companies that perform residential work. These companies are represented by trade organizations such as the NAHB.[11]

Prime contractor is a term defined in the US law.[12][13] Statutory definitions of prime contract, prime contractor, subcontract, and subcontractor are in 41 U.S.C. § 8701.[14] The prime contractor term was already defined before the 8 March 1946 passage of An Act To eliminate the practice by subcontractors, under cost-plus-a-fixed-fee or cost reimbursable contacts of the United States, of paying fees or kick-backs, or of granting gifts or gratuities to employees of a cost-plus-a-fixed-fee or cost reimbursable prime contractors or of higher tier subcontractors for the purpose of securing the award of subcontracts or orders. (Pub. L.Tooltip Public Law (United States) 79–319, 60 Stat. 37)

Licensing requirements to work legally on construction projects vary from locale to locale. In the United States, there are no federal licensing requirements to become a general contractor, but most US states require general contractors to obtain a local license to operate. It is the states' responsibility to define these requirements: for example, in the state of California, the requirements are stated as follows:

With a few exceptions, all businesses or individuals who work on any building, highway, road, parking facility, railroad, excavation, or other structure in California must be licensed by the California Contractors State License Board (CSLB) if the total cost of one or more contracts on the project is $500 or more.

In every state that requires a license, a surety bond is required as part of the licensing process, with the exception of Louisiana, where bonding requirements may vary in different parishes. Not all states require General Contractor licenses - these include Vermont, New Hampshire and Maine, among others.

Some general contractors obtain bachelor's degrees in construction science, building science, surveying, construction safety, or other disciplines.

General Contractors often learn about different aspects of construction, including masonry, carpentry, framing, and plumbing. Aspiring general contractors communicate with subcontractors and may learn the management skills they need to run their own company.

Experience in the construction industry as well as references from customers, business partners, or former employers are demanded. Some jurisdictions require candidates to provide proof of financing to own their own general contracting firm.

General Contractors often run their own business. They hire subcontractors to complete specialized construction work and may manage a team of plumbers, electricians, bricklayers, carpenters, iron workers, technicians, handymans, architects and roofers. General Contractors build their business by networking with potential clients, buying basic construction tools, and ensuring that their subcontractors complete high-quality work. General Contractors do not usually complete much construction work themselves, but they need to be familiar with construction techniques so they can manage workers effectively. Other reasons include access to specialist skills, flexible hiring and firing, and lower costs.

A property owner or real estate developer develops a program of their needs and selects a site (often with an architect). The architect assembles a design team of consulting engineers and other experts to design the building and specify the building systems. Today contractors frequently participate on the design team by providing pre-design services such as providing estimations of the budget and scheduling requirements to improve the economy of the project. In other cases, the general contractor is hired at the close of the design phase. The owner, architect, and general contractor work closely together to meet deadlines and budget. The general contractor works with subcontractors to ensure quality standards; subcontractors specialise in areas such as electrical wiring, plumbing, masonry, etc.

| |

| Names | |

|---|---|

| Other names

polybutene-1, poly(1-butene), PB-1

| |

| Identifiers | |

| ChemSpider |

|

| ECHA InfoCard | 100.111.056 |

CompTox Dashboard (EPA)

|

|

| Properties | |

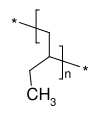

| (C4H8)n | |

| Density | 0.95 g/cm3[1] |

| Melting point | 135 °C (275 °F; 408 K)[1] |

| Related compounds | |

Related compounds

|

1-butene (monomer) |

Except where otherwise noted, data are given for materials in their standard state (at 25 °C [77 °F], 100 kPa).

| |

Polybutylene (polybutene-1, poly(1-butene), PB-1) is a polyolefin or saturated polymer with the chemical formula (CH2CH(Et))n. Not be confused with polybutene, PB-1 is mainly used in piping.[2]

Polybutylene is produced by polymerisation of 1-butene using supported Ziegler–Natta catalysts.

Isotactic PB-1 is produced commercially using two types of heterogeneous Ziegler–Natta catalysts.[3] The first type of catalyst contains two components, a solid pre-catalyst, the δ-crystalline form of TiCl3, and solution of an organoaluminum cocatalyst, such as Al(C2H5)3. The second type of pre-catalyst is supported. The active ingredient in the catalyst is TiCl4 and the support is microcrystalline MgCl2. These catalysts also contain special modifiers, organic compounds belonging to the classes of esters or ethers. The pre-catalysts are activated by combinations of organoaluminum compounds and other types of organic or organometallic modifiers. Two most important technological advantages of the supported catalysts are high productivity and a high fraction of the crystalline isotactic polymer they produce at 70–80 °C under standard polymerization conditions.[4][5][6]

PB-1 is a high molecular weight, linear, isotactic, and semi-crystalline polymer. PB-1 combines typical characteristics of conventional polyolefins with certain properties of technical polymers.

PB-1, when applied as a pure or reinforced resin, can replace materials like metal, rubber and engineering polymers. It is also used synergistically as a blend element to modify the characteristics of other polyolefins like polypropylene and polyethylene. Because of its specific properties it is mainly used in pressure piping, flexible packaging, water heaters, compounding and hot melt adhesives.

Heated up to 190 °C and above, PB-1 can easily be compression moulded, injection moulded, blown to hollow parts, extruded, and welded. It does not tend to crack due to stress.[dubious – discuss] Because of its crystalline structure and high molecular weight, PB-1 has good resistance to hydrostatic pressure, showing very low creep even at elevated temperatures.[7] It is flexible, resists impact well and has good elastic recovery.[3][8]

Isotactic polybutylene crystallizes in three different forms. Crystallization from solution yields form-III with the melting point of 106.5 °C. Cooling from the melt results in the form II which has melting point of 124 °C and density of 0.89 g/cm3. At room temperature, it spontaneously converts into the form-I with the melting point of 135 °C and density of 0.95 g/cm3.[1]

PB-1 generally resists chemicals such as detergents, oils, fats, acids, bases, alcohol, ketones, aliphatic hydrocarbons and hot polar solutions (including water).[3] It shows lower resistance to aromatic and chlorinated hydrocarbons as well as oxidising acids than other polymers such as polysulfone and polyamide 6/6.[7] Additional features include excellent wet abrasion resistance, easy melt flowability (shear thinning), and good dispersion of fillers. It is compatible with polypropylene, ethylene propylene rubbers, and thermoplastic elastomers.

Some properties:[7]

The main use of PB-1 is in flexible pressure piping systems for hot and cold drinking water distribution, pre-insulated district heating networks and surface heating and cooling systems. ISO 15876 defines the performance requirements of PB-1 piping systems.[9] PB-1's most notable characteristics are weldability, temperature resistance, flexibility and high hydrostatic pressure resistance. The material can be classified PB 125 with a minimum required strength (MRS) of 12.5 MPa. Other features include low noise transmission, low linear thermal expansion, no corrosion and calcification.

PB-1 piping systems are no longer being sold in North America (see "Class action lawsuits and removal from building code approved usage", below). The overall market share in Europe and Asia is rather small but PB-1 piping systems have shown a steady growth in recent years. In certain domestic markets, e.g. Kuwait, the United Kingdom, Korea and Spain, PB-1 piping systems have a strong position.[8]

Several PB-1 grades are commercially available for various applications and conversion technologies (blown film, cast film, extrusion coating). There are two main fields of application:

PB-1 is compatible with a wide range of tackifier resins. It offers high cohesive and adhesive strength and helps tailoring the "open time" of the adhesive (up to 30 minutes) because of its slow crystallisation kinetics. It improves the thermal stability and the viscosity of the adhesive.[10]

PB-1 accepts very high filler loadings in excess of 70%. In combination with its low melting point it can be employed in halogen-free flame retardant composites or as masterbatch carrier for thermo-sensitive pigments. PB-1 disperses easily in other polyolefins, and at low concentration, acts as processing aid reducing torque and/or increasing throughput.

PB-1 can be foamed.[11] The use of PB-1 foam as thermal insulation is of great advantage for district heating pipes, since the number of materials in the sandwich structure is reduced to one, facilitating its recycling.[12]

Other applications include domestic water heaters, electrical insulation, compression packaging, wire and cable, shoe soles, and polyolefin modification (thermal bonding, enhancing softness and flexibility of rigid compounds, increasing temperature resistance and compression set of soft compounds).

Plumbing and heating systems made from PB-1 have been used in Europe and Asia for more than 30 years. First reference projects in district heating and floor heating systems in Germany and Austria from the early 1970s are still in operation today.[8]

One example is the installation of PB-1 pipes in the Vienna Geothermal Project (1974) where aggressive geothermal water is distributed at a service temperature of 54 °C and 10 bar pressure. Other pipe materials in the same installation failed or corroded and had been replaced in the meantime.[8]

International standards set minimum performance requirements for pipes made from PB-1 used in hot water applications. Standardized extrapolation methods predict lifetimes in excess of 50 years at 70 °C and 10 bar.[8]

Polybutylene plumbing was used in several million homes built in the United States from around 1978 to 1997. Problems with leaks and broken pipes led to a class action lawsuit, Cox v. Shell Oil, that was settled for $1 billion.[13][14] The leaks were associated with degradation of polybutylene exposed to chlorinated water.[15]

Polybutylene water pipes are no longer accepted by the United States building codes and have been the subject[16] of class action lawsuits in both Canada and the U.S.[17][18] The National Plumbing Code of Canada 1995 listed polybutylene piping as acceptable for use with the exception of recirculation plumbing. The piping was removed from the acceptable for use list in the 2005 issue of the standard.[19]

In Australia in March 2023, the Department of Mines, Industry Regulation and Safety reported that Australian homes built in 2019-2020 that had used a certain brand of polybutylene piping, had become the subject of an enquiry due to the significance of water leaks reported.[20][21]

There is evidence to suggest that the presence of chlorine and chloramine compounds in municipal water (often deliberately added to retard bacterial growth) will cause deterioration of the internal chemical structure of polybutylene piping and the associated acetal fittings.[22] The reaction with chlorinated water appears to be greatly accelerated by tensile stress, and is most often observed in material under highest mechanical stress such as at fittings, sharp bends, and kinks. Localized stress whitening of the material generally accompanies and precedes decomposition of the polymer. In extreme cases, this stress-activated chemical "corrosion" can lead to perforation and leakage within a few years, but it also may not fail for decades. Fittings with a soft compression seal can give adequate service life.[further explanation needed]

Because the chemical reaction of the water with the pipe occurs inside the pipe, it is often difficult to assess the extent of deterioration. The problem can cause both slow leaks and pipe bursting without any previous warning indication. The only long-term solution is to completely replace the polybutylene plumbing throughout the entire building.[23]

When considering any project, you've got to weigh the costs. It's not just about the upfront expenses; think about long-term savings, too. Don't forget, replacing outdated materials now can save you a bundle later.

You're likely wondering about the environmental impact of replacing polybutylene pipes. It's a smart move, as it reduces potential water waste from leaks and uses more eco-friendly materials, benefiting both the planet and your conscience.

Replacing polybutylene pipes in your home can significantly increase its value and may lower your insurance premiums over time, as it reduces the risk of water damage from pipe failures. It's a smart long-term investment.